FAT and GMP: IMPORTANT LINKS IN THE INVESTMENT PROJECT FOR PHARMACEUTICAL PLANT DEVELOPMENT

The Vietnamese pharmaceutical industry is a promising market for development in Asia with increasing demand thanks to the growing population, improved income, increasing urbanization and other environmental conditions. 1

To meet the increasing demand, many large domestic and foreign pharmaceutical manufacturers have invested in upgrading their plants, aiming to break through the development of new pharmaceutical products to improve treatment quality and accessibility to the community. However, the procurement of equipment always poses a significant challenge for the project staff. The question in each member of the project team is how to get the best equipment, all risks in production later must be tightly controlled to ensure that the final product supplied to the community meets the desired quality level

To ensure that the output product is safe, meets standards, minimizes defects and recalls, and optimizes resources. Tien Tuan understands that instead of hoping for the best - we plan for the best.

Factory Acceptance Test - What is FAT?

Factory Acceptance Test – FAT is a set of tests that are defined and planned in advance to demonstrate suitability for use according to customer requirements, performed at the Supplier’s factory before delivery.

A typical FAT involves customer representatives present at the factory for 2-3 days (or more). The personnel involved may vary depending on the technical requirements of the product and the objectives of the project, generally including: production, QA, mechanical and electrical, to confirm that the equipment is manufactured according to design and customer expectations.2

The main components of a FAT program

- The FAT qualification process is carried out based on a pre-approved plan and outline.

- The qualification report based on the approved outline specifies whether the test items PASS or FAIL.

- In case of a FAIL test, the content will be recorded and mentioned in the post-FAT meeting, then both parties will discuss and give opinions and corrective measures.

Since after the COVID pandemic, FAT activities have gradually shifted to online or online combined with fieldwork with many connection points to simultaneously maximize observations and records on equipment quality.

Position, role and benefits of FAT in the project implementation process

FAT is not only beneficial for the buyer but also for the equipment supplier. For the equipment supplier, correcting technical characteristics as soon as the system is still at the manufacturing plant helps minimize costs and time for repair and remediation.

For example, a mold detail of a blister machine was found to be unsuitable during FAT, resulting in a tablet blister that did not pass the leak test, the equipment manufacturer could immediately investigate the cause and remedy it within a day. If there is no FAT, this error is detected at the place of use, it will take time to move for experts, costly raw materials to test run, human resources, energy of the buyer. From there, it causes a large increase in budget and progress for the total project for a small technical error.

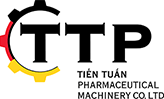

Lưu đồ 1 3

For the buyer, according to the recommended flowchart of GAMP5 above, FAT is performed after completing Design Qualification (DQ), when the equipment has been fully manufactured, to determine whether the equipment meets all functions based on initial expectations or not.

After successful FAT, the equipment will be dismantled for transportation. At the plant of the user, the equipment is completely reassembled and tested at the place of use, this process is called Site Acceptance Test (SAT).

Ergonomic survey in FAT at TTP helps SAT process more smoothly

Complete FAT documentation makes it easy to switch to SAT, quality assessment and continuous monitoring.

The equipment will then have to go through installation qualification (IQ), operational qualification (OQ) and performance qualification (PQ) activities to demonstrate that user requirements and drug laws have been fully met, GMP risks are well controlled before starting production of test batches.

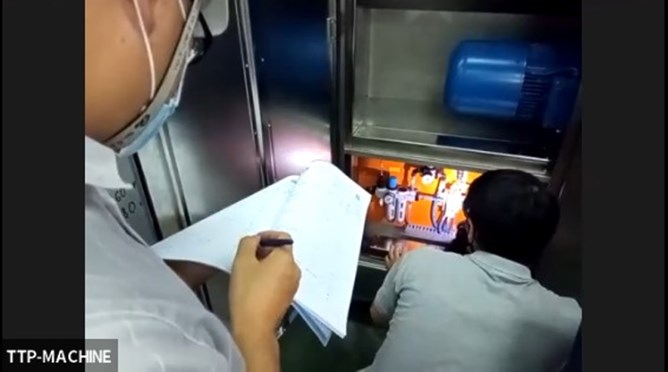

IQ tasks such as checking material fabrication, diagrams, equipment drawings, checking power sources,… are also reviewed in FAT

+ Checking material fabrication helps detect and limit rusting of machine parts during later operation.

+ Checking diagrams and drawings to ensure that equipment parts are manufactured and assembled according to design and ensure that information for maintenance is complete and accurate.

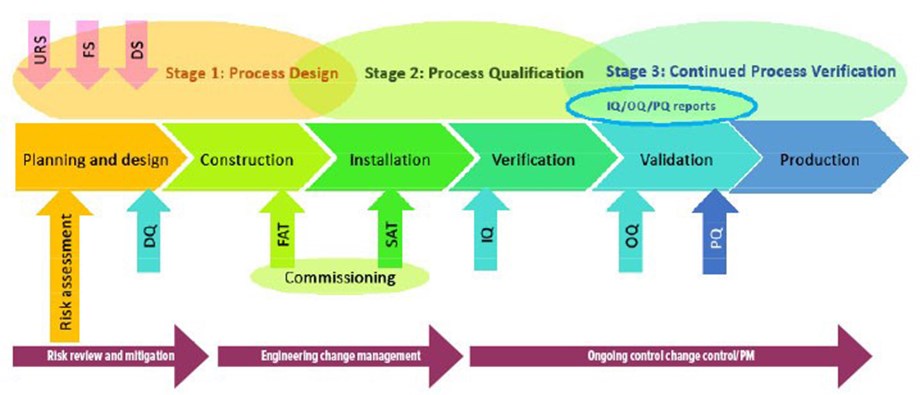

Customer checks compressed air source during FAT process at TTP

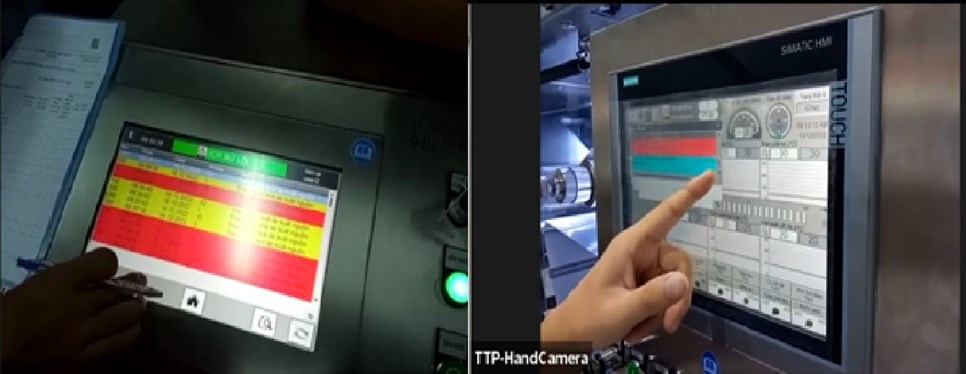

Operational Qualification OQ is documented proof that the functions on the equipment operate according to their approved design. Standard Operating Procedures (SOPs), maintenance, calibration, sanitation will also be built in this operational qualification phase.

Testing alarms and setting product parameters during FAT at TTP

Setting product run parameters on placebo tablets during FAT also helps save time and resources for OQ process to run more smoothly with pre-predicted scenarios.

In summary, the FAT process has significantly shortened the time for later stages of the project, helping to speed up progress as well as tightly control risks and contribute significantly to the success of each project.

REFERENCE INFORMATION

1 Assessment from Vietnam Briefing page.

https://www.vietnam-briefing.com/news/vietnams-growing-pharmaceutical-industry.html/

2 2008 - ISPE’s GAMP® 5: A Risk-Based Approach to Compliant GxP Computerized Systems

3 Pharmaceutical Engineering Home. ISPE. (2023, January 1). Retrieved January 13, 2023, from https://ispe.org/pharmaceutical-engineering

READ MORE

Selecting pharmaceutical machinery is a critical process that requires careful consideration to ensure compliance with regulatory requirements, product quality and operational efficiency.

In the ever-evolving landscape of pharmaceutical manufacturing, precision and efficiency take center stage. Our cutting-edge Auto Coating System revolutionizes the coating process, ensuring optimal product quality and streamlined operations. Let’s explore the key features that set our system apart:

Tien Tuan is thrilled to unveil our latest innovation in pharmaceutical containment technology – the Dispensing Isolator.

Some of challenges and typical benefits briefly of blister packing Fentanyl Citrate

Selecting pharmaceutical equipment is a critical process that requires careful consideration of various factors:

Child-resistant blister packaging is designed to prevent young children who may be curious and explore their environment from accessing and potentially ingesting harmful substances such as medications, yet remain relatively easy for adults to access.

The wet granulation process in two separate steps is the most widely used technology and it is suitable for traditional drug mixing equipment such as Mixer & Granulator and Fluid-bed Dryer & Granulator.

The one-step granulation process helps to create granules directly, by granulating acid and alkali granules together. Usually, water is used as a granulation solution, so the effervescent reaction must be controlled during the granulation process. Ethanol or propanol can also be used as a granulation solution, but then additional binders are needed to achieve the necessary cohesion. There are 2 types of equipment used to prepare effervescent tablets according to this technology

Effervescent tablets have the main advantage of being easy to use, especially effective for patients who are children. However, their production is more complicated than traditional tablets, especially the selection of technology and equipment.

The effects of the new variant are difficult to announce accurately because unlike previous variants, Omicron mainly attacks young people who have better resistance.

Signing ceremony for cooperation in supplying fully automatic blistering cartoning line according to GMP-EU standard for US PHARMA

The Covid-19 pandemic has posed new challenges for pharmaceutical startups. What needs to be done to survive and develop, especially in this period. The StartUs Insight newspaper based on the analysis of “1745 famous pharmaceutical startups in 2020”, found the most outstanding startups. To turn challenges into opportunities, pharmaceutical companies have had “tips” for startups to survive the pandemic.

Checking the punches and dies and the components of the tablet press for wear or damage is one of the very important steps to improve the quality of the tablets. There are some points to check that we easily overlook but can cause significant quality problems for the tablets and reduce the life of the punches and dies. So take some time to check the following points to determine their wear or defects and quickly improve the quality of the tablets and reduce the cost of punches and dies

If you are interested in beauty, you must have heard of collagen skin care. Even many cosmetic companies have launched products that contain collagen, such as moisturizers, lotions, serums, etc.

Ở một số nơi, khi số ca mắc #COVID-19 giảm xuống, một số biện pháp phòng chống dịch đang được gỡ bỏ...

Ngành công nghiệp dược phẩm tuân theo các yêu cầu khắt khe nhất đối với quá trình sản xuất và thiết bị được sử dụng phải tuân thủ thực hành sản xuất tốt (GMP). Khi xu hướng phát triển thuốc thay đổi, các quy trình sản xuất cũng phải thay đổi, phần lớn trong số đó hiện có thể được tự động hóa...

Cuộc khủng hoảng y tế COVID-19 mang lại những tác động và tiến bộ khoa học mạnh mẽ đồng thời cũng rút ra được những bài học kinh nghiệm quý báu cho các doanh nghiệp, tổ chức và các quốc gia trên thế giới:

Tại Trung tâm chống dộc Bệnh viện Bạch Mai đã tiếp nhận rất nhiều trường hợp bị ngộ độc do lạm dụng thuốc hạ sốt paracetamol để chữa COVID-19. Do đó, người dân nên cẩn trọng trước các bài thuốc lan truyền không rõ nguồn gốc trên mạng xã hội, trước khi sử dụng bất kỳ loại thuốc nào cần xin ý kiến bác sĩ, không được tự ý sử dụng.

Từ ngày 1/8/2021 doanh nghiệp có thể tra cứu trạng thái chứng nhận xuất xứ mẫu D trên internet. Đồng thời các doanh nghiệp nhập khẩu các lô hàng thuốc, nguyên liệu làm thuốc nhập khẩu luồng đỏ phải xuất trình bản gốc giấy uỷ quyền, giấy phép lưu hành và phiếu kiểm nghiệm sản phẩm

Hiệp định thương mại tự do Việt Nam - EU (EVFTA) có hiệu lực từ tháng 8/2020 mở ra nhiều cơ hội trong quan hệ đối tác toàn diện giữa hai bên. Tác động của EVFTA đến ngành dược phẩm đã có những kết quả dần rõ nét, đặc biệt là đối với các doanh nghiệp Châu Âu.

Việc duy trì sản xuất và giao hàng đúng hạn, giữ đúng cam kết với khách hàng là nỗ lực đáng ghi nhận, thể hiện uy tín, nội lực và sức cạnh tranh cao của Tiến Tuấn.

Theo Đại sứ quán Việt Nam tại Ấn Độ, đây là gợi ý được các ông lớn trong ngành dược phẩm Ấn Độ đưa ra trong buổi họp xúc tiến thương mại đầu tư do Đại sứ Việt Nam tại Ấn Độ - ông Phạm Sanh Châu chủ trì.