PROVIDING

TURN-KEY SOLUTION

Consulting - Designing - Manufacturing - Providing solutions for production of oral solid dosage form in the pharmaceutical industry.

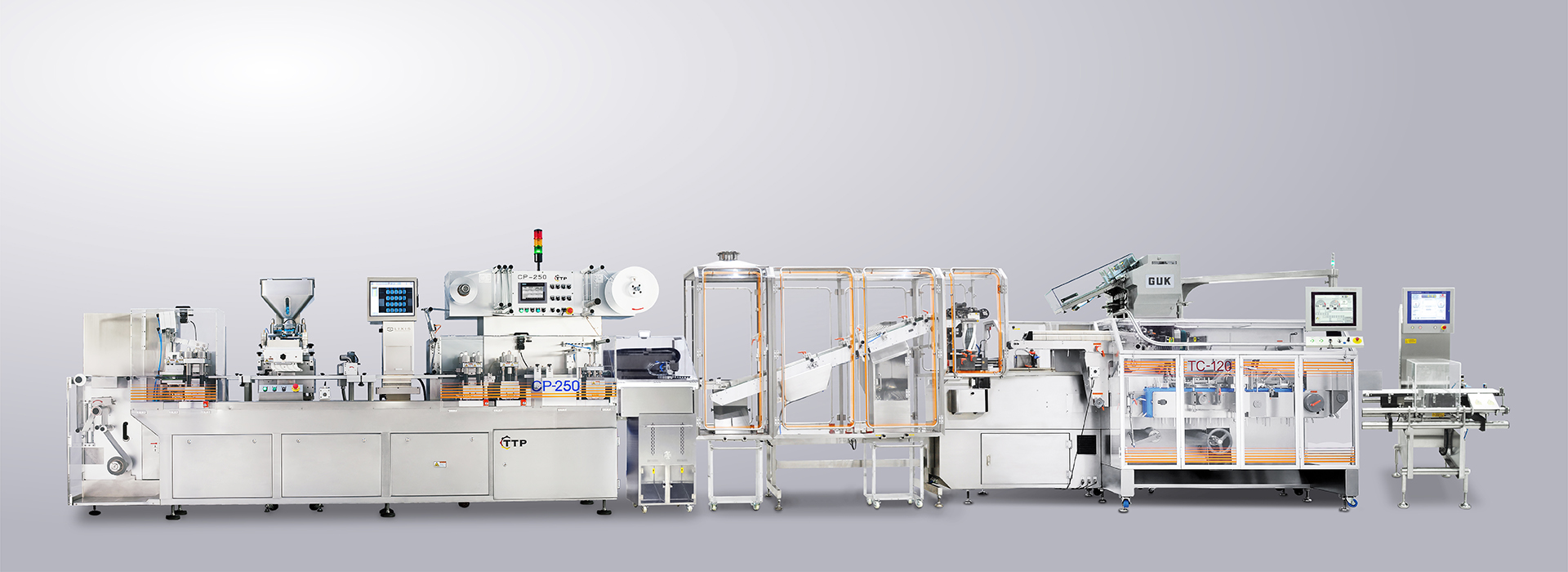

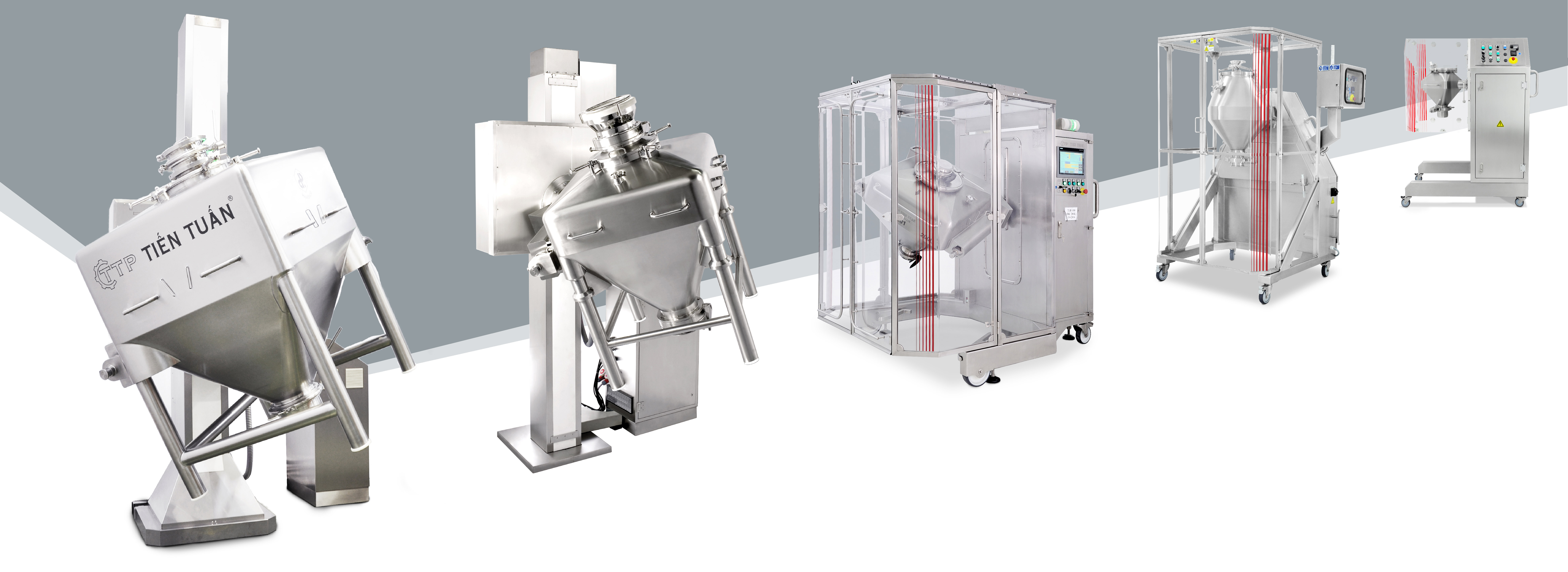

Tien Tuan specializes in consulting - designing - manufacturing automatic machinery and equipment and providing package solutions for oral solid dosage pharmaceutical manufacturing plants according to cGMP, GAMP5, EU-GMP, PIC/s of the pharmaceutical industry.

With the quality policy "German standard - made in Vietnam" with modern and advanced design, strict production and inspection process, most of the components are imported from reputable firms in Germany and Europe, Tien Tuan's products have been used widely by many famous pharmaceutical companies in Vietnam and around the world such as Asia, the Middle East, Europe, Australia, Africa and America.

our quality systems

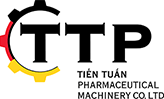

Production line

Tien Tuan is proud to provide high quality products "German standard - made in Vietnam" to all over the world

NEWS

Tien Tuan has successfully completed the FAT for the FM-800i hammer mill, specifically designed for sugar grinding in pharmaceutical production, with direct witness from the customer at the factory.

Blister packaging plays a vital role in shielding active ingredients from moisture, oxygen, and light, ensuring product stability throughout its shelf life.

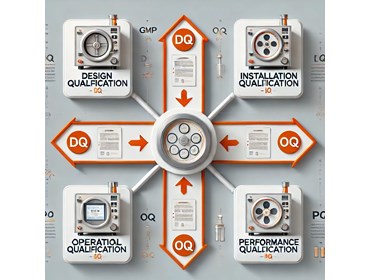

In the pharmaceutical industry, equipment must not only be modern — it must be validated to ensure safety, consistency, and GMP compliance.

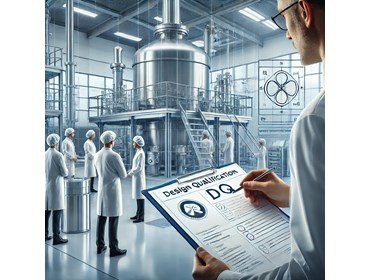

In the pharmaceutical industry, investing in machinery is not just about cost—it is also about quality, GMP compliance, and production optimization. That’s why DQ - Design Qualification is a mandatory step to ensure that equipment meets the right requirements from the beginning!

In the pharmaceutical industry, choosing machinery is not just about price or technology—it must also meet strict quality standards. This is where URS (User Requirement Specification) plays a crucial role!